Distributors of

SPEED -O CONTROL

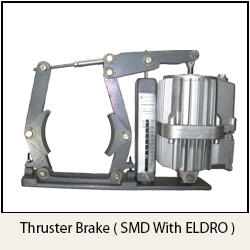

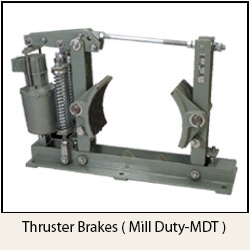

Thruster Brakes

Thruster brake is a device to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed compression spring. The shoes press on the rotating brake drum retarding its speed, and finally stopping it. The releasing of the brake and compressing of the spring is done by thruster.

• Thruster Brake Series - SMD with Eldro (150mm - 710mm)

• Thruster Brake Series - Mill Duty MDT (100mm - 250mm)

• Thruster Brake Series - Mill Duty MDT (300mm - 600mm)

Limit Switches

Rotary Geared Limit Switch GRLS is used to trip motor supply when the moving load reaches the extreme end positions of working zone. The driving motion is transmitted by worm gear through worm shaft. The rotations and movements are transmitted to switches by adjustable cams. Worm Drive Limit Switch FGLS are suitable for use on reversing drives, such as Hoists, Cranes, Winches, Rolling Mills, Theater Curtains, Coke Oven etc. The driving motion is transmitted by worm gear. All gears and hubs are made of low wear thermoplastic material. The rotational movements are transmitted to switches by adjustable cams. Limit Switch LSR Cross Rotary for travel Motion Operates the control change over the contacts of a motor of a moving equipment which when operates with a load a actuates the 300mm rods of the Limit Switch and this in turn operates the NO/NC change-over contact elements.

Resistance Box

Resistance Boxes are used to add resistance into an electric motor circuit for modifying the performance characteristic of slipring induction motors of EOT cranes, rubber mills, steel rolling mills, cement mills, power plants, coke oven, blowers etc. or speed control and developing starting torque with low starting currents. They are also used as Dynamic breaking resistor for V.V.F.A.C. Drives, electric loading of ac alternators, de generators and dynamometers. Resistors are designed to meet requirements of both A. C. & D. C. Applications.

Types of Resistors :

• Punched Grid Resistors (Stainless Steel/Feehral)

• Stainless steel wire grid resistors

Types of Cooling :

• Air cooled type

• Oil cooled type

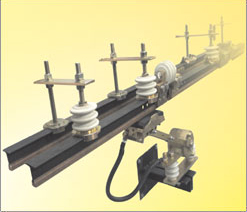

Rail Systems

Specifications

Individual conductors installed on insulators for high amperage / high voltage heavy duty applications

Product Overview

Copperhead Conductor System: a copper bar mounted onto a T-shaped steel section. The copper bar transfers the electrical current, and the T-bar provides greater strength and more reliable electrical contact.

Product Advantages

Copperhead Conductor System: a copper bar mounted onto a T-shaped steel section. The copper bar transfers the electrical current, and the T-bar provides greater strength and more reliable electrical contact.

• Copperhead rails ensure efficient and continuous electrical contact

• Increased safety due to elimination of sparking

• Cost savings from reduced maintenance needs

• Significantly reduced component wear for increased component life expectancy

• Lower resistance between copper and pickup shoe of mobile component

• Lower weight means lighter support structures and reduced space needs

• Standard expansion joints used to compensate for expansion and contraction due to temperature changes

• Curved or bent Copperhead rails available on request and customized to your precise specifications

• For low-temperature environments, heating systems available for all rails

Main Applications

Today, Copperhead conductor rails are the proven solution for safe power transmission in a variety of heavy-duty applications, including:

• Travelling cranes • Container handling equipment • Hoists

• Loading bridges • Monorails • Coking machinery